Welcome to Our Company

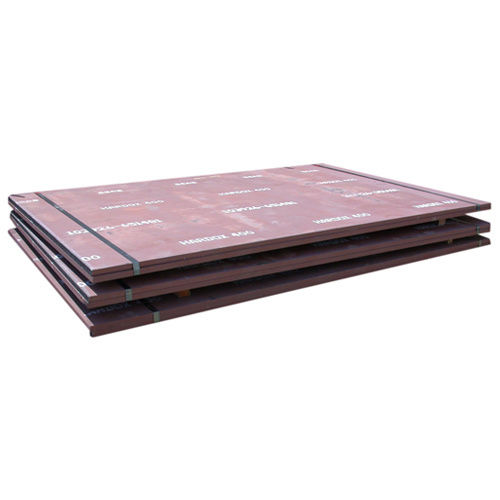

ROCKHARD 500 Plates

900 USD ($)/Ton

Product Details:

- Product Name Abrasion Resistant Plate

- Thickness 3-200 Millimeter (mm)

- Surface EP, PE, HDP, SMP, PVDF

- Application Construction

- Dimension (L*W*H) L-1000 - 12000mm, W-500 - 3000mm Millimeter (mm)

- Click to View more

X

ROCKHARD 500 Plates Price And Quantity

- 1 Ton

- 900 USD ($)/Ton

ROCKHARD 500 Plates Product Specifications

- L-1000 - 12000mm, W-500 - 3000mm Millimeter (mm)

- Construction

- EP, PE, HDP, SMP, PVDF

- 3-200 Millimeter (mm)

- Abrasion Resistant Plate

ROCKHARD 500 Plates Trade Information

- Cash in Advance (CID)

- 5000 Ton Per Month

- 7 Days

- All India

Product Description

BRAND OF ROCKSTAR 500 PLATES

Brand | Manufacture/Co | HARDNESS RANGE | C.E.V. Typical Values |

Values for BHN 500 | Thk: 10 20 | ||

BHN 400 | SSAB | 370-430 | 0.37 |

QUARD 400 | DUFERCO | 370-430 | 0.42 |

JFE EVERHARD 360LE | JFE STEEL CORPN. | 360-430 | 0.38 |

SUMIHARD K400 | SUMITOMO METALS | 400-440 | 0.46 |

ABRAZO 400 | TATA UK LTD. | 360-430 | 0.43 |

RAEX 400 | RUUKKI | 360-430 | 0.43 |

DILLIDUR 400V | DILLINGER HUTTE | 370-430 | 0.43 |

XAR 400 | THYSSEN KRUPP | 370-430 | 0.43 |

BRINAR 400 | ILSENBURGER GROBBLECH | 360-430 | 0.48 |

FORA 400 | INDUSTEEL | 360-430 | 0.48 |

HARDPLAST 380 | ISD HUTA | 360-430 | 0.56 |

NICRODUR 400 | ACRONI | 360-430 | 0.56 |

CREUSABRO 4800 | INDUSTEEL | 360-430 | 0.48 |

WELHARD 400 | NSC/JAPAN | 400-440 | 0.46 |

BIS Plate 320 | Bisalloy Steels Pty Ltd | 320-360 | 0.4 |

BIS Plate 400 | Bisalloy Steels Pty Ltd | 370-430 | 0.4 |

BIS Plate 450 | Bisalloy Steels Pty Ltd | 425-475 | 0.48 |

Rockstar 400 | Essar Steel India Ltd. | 370-430 | 0.45 |

Rockstar 450 | Essar Steel India Ltd. | 425-475 | 0.52 |

Rockstar 500 | Essar Steel India Ltd. | 450-540 | 0.6 |

Abrex 400 | NSSMC | 360-440 | 0.4 |

Abrex 450 | NSSMC | 410-490 | 0.5 |

Abrex 500 | NSSMC | 450-550 | 0.55 |

Abrex 600 | NSSMC | 550-650 | 0.73 |

SPECIFICATION

| Item | Abrasion Resistant Plate |

|---|---|

| Material | ROCKSTAR 500, SUMIHARD, BRINAR, DUROSTAT, DILLIDUR, JFE EVERHARD. |

| Thickness | 3 - 200mm |

| Width | 500 - 3000mm |

| Length | 1000 - 12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

CHEMICAL COMPOSITION OF ROCKSTAR 500 PLATES

Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

4-13 | 0.27 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.25 | 0.25 | 0.004 | 0.49 | 0.34 |

(13)-32 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 0.50 | 0.30 | 0.004 | 0.62 | 0.41 |

32-40 | 0.29 | 0.7 | 1.6 | 0.025 | 0.01 | 1.00 | 1.00 | 0.60 | 0.004 | 0.64 | 0.43 |

40-80 | 0.30 | 0.7 | 1.6 | 0.025 | 0.01 | 1.50 | 1.50 | 0.60 | 0.004 | 0.74 | 0.46 |

MECHANICAL PROPERTIES OF ROCKSTAR 500 PLATES

Mechanical Property | Charpy V Impact Test | |||

HBW Thickness/Mpa | Elongation | Degree | longitudinal | |

4-32MM | 470-530 | Min % | -40 | J |

(32)-80 | 450-540 | 10 | 40 | |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email