Welcome to Our Company

Showroom

Boiler Quality IBR Plates are carbon steel, plates specifically rolled to be put up with Boiler and all kinds of high-pressure pressure vessels. Mostly used by boiler manufacturing companies and power houses in which these are in need of heavy steam at High pressure, and for boiling water and etc. Manufactured from Tensile steel that holds strength in heavy pressure conditions and it provides resistance while being applied to high pressure along with elevated temperature.

Pressure Vessel is a container that stores fluids or gases at high pressure. Pressure vessels are greatly in use in such industries as chemical, oil and gas, power generating, food and beverage, and pharmaceuticals. Carbon steel is the most common manufacturing material used for pressure vessels, with good strength, availability, and being cost-effective. The design of a pressure vessel is very sensitive to the internal pressure, temperature, type of contents, and operating conditions.

Alloye Steel Plate is widely used in all industries such as automotive, aerospace, construction, oil and gas, power generation, and manufacture of heavy machinery. Due to versatility and the ability to work in extreme conditions, they are in huge demand for applications that need superior mechanical properties. The material is crucial in an extensive range of industries based on its superior strength, toughness, and resistance to wear and corrosion.

S690QL Plates are designed to be a high strength, quench and tempered structural steel plate that provides good yield strength, weldability, and formability for applications that demand the same in demanding structural applications. The variety in shapes and sizes allows the steel grade to be shaped into different forms and sizes and is versatile for cutting, punching, and machining fabrication processes.

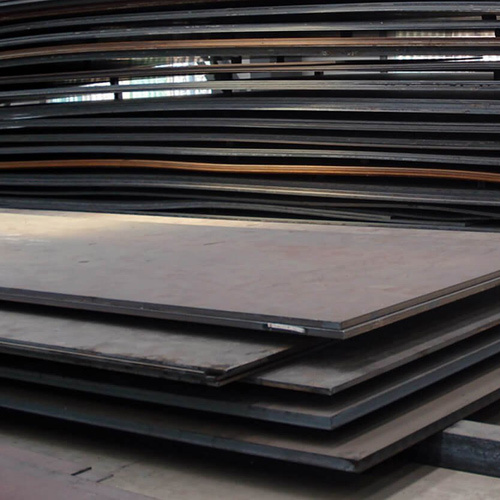

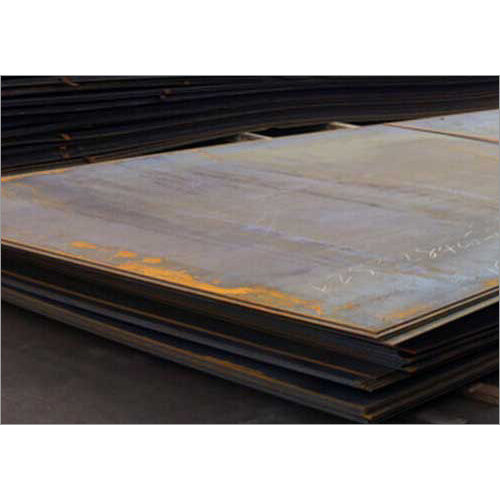

Abrison Resistant Plates are a type of steel that is designed to give resistance to wear and tear created by friction and impact. They are engineered to stay resistant against aggressive mechanical processing that would wear out some other materials, giving them superior hardness and durability in tough environments. They come in a variety of hardness levels and can be developed to meet the specific demands of each industry, from very light to extreme abrasive environments.

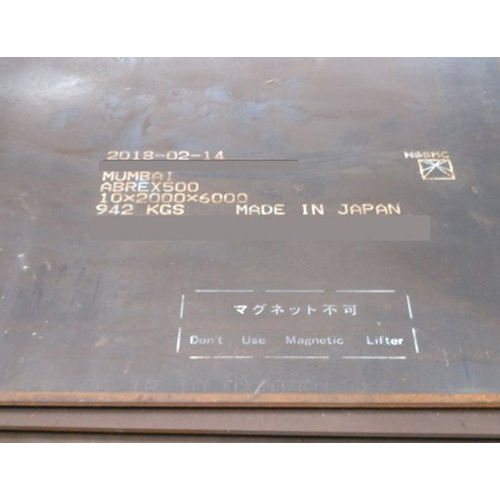

Abrex Plates is engineered to meet abrasion resistance in some high-friction or abrasion applications such as gravel, ore, sand, or steel scrap. Despite the high hardness level, these plates have reasonable weldability, which is really needed for fabrication and construction of parts. Its usage range is flexible with respect to the hardness level. It allows for both light and heavy-duty applications. Additionally, it offers high toughness and structural resistance even under harsh conditions.

JFE Plates possess high performance, durability, and excellent mechanical properties, which make them a preferred choice for demanding applications. These plates are available in a wide range of thicknesses and can be further customized to meet specific needs. They are used to construct industrial equipment such as tanks, pressure vessels, and pipelines in the petrochemical and chemical industries.

Rockstar Steel Plates are one type of high-strength abrasion-resistant (AR) steel plates that are particularly manufactured to be used in adverse conditions that involve heavy usage, especially wear and tear. This generally increases the longevity of machineries and equipment with respect to wear and tear because these materials provide superior protection and ultimately cut the cost of maintenance along with downtime. Rockstar steel plates are also manufactured in various thicknesses and sizes to fit all possible needs of applications.

Quard Plates are designed with high wear resistance and toughness to be used in the conditions of material abrasion, impact, and friction. They have high wear resistance and can be applied in areas where they would be subjected to high abrasive forces, such as rocks, soil, and metal scraps. They come in a range of thicknesses and can be made to size for special requests for particular equipment and machinery.

BHN Hard Plates have been engineered to provide great abrasion resistance, impact resistance, and durability when materials experience constant wear or harsh operating conditions. Since these plates are so hard and resistive to wear, they allow for extended service lives of machines and equipment. These plates also shield against excessive material flow that may damage the machine, and help ensure the system runs uninterrupted with less frequent stops for maintenance.

NM Plate is a high-strength abrasion-resistant steel applied for heavy-duty applications when parts and components are exposed to hard wear conditions. These are designed as weldable for easy incorporation into larger systems or to make custom-fabricated components such as bucket liners, crusher parts, and chutes. The inclusion of niobium helps enhance the strength and toughness of NM plates even with higher hardness levels.